Technology is on its edge of development nowadays, Czinger 21C is the live example of this bleeding edge technology, in this article we will talk about the Czinger21C in shortest way possible.

|

Designed under the direction of former Mitsubishi designer Dave O'Connell, the 21C is a compact, muscular-looking thing, with jet-fighter-style seating that positions the passenger behind the driver under a long, narrow, central canopy. Inspirations for that, Kevin Czinger says, included the iconic SR-71 Blackbird spy plane, the Bell X-1 in which Chuck Yeager broke the sound barrier, Top Gun's F-14 Tomcat, and Star Wars movie spaceships.

Even with modern hypercar standards, the numbers cited by Czinger are impressive: 0-60 mph in 1.9 seconds; a quarter of a mile made and dust removed in 8.1 seconds; 0-186 mph in 15 seconds; 0-248 mph and return to a standstill in an amazing 29 seconds. In road specification, the 21C has a top speed of 268 mph and produces 551 pounds of downforce at 155 mph. The track type comes out at just 236 mph due to a pull from the large rear wing that contributes to 1,742 pounds of low power at 155 mph. "This car is designed for record hunting," said Kevin Czinger. Not played.

There are two factors that make 21C operation possible: high power density and low weight.

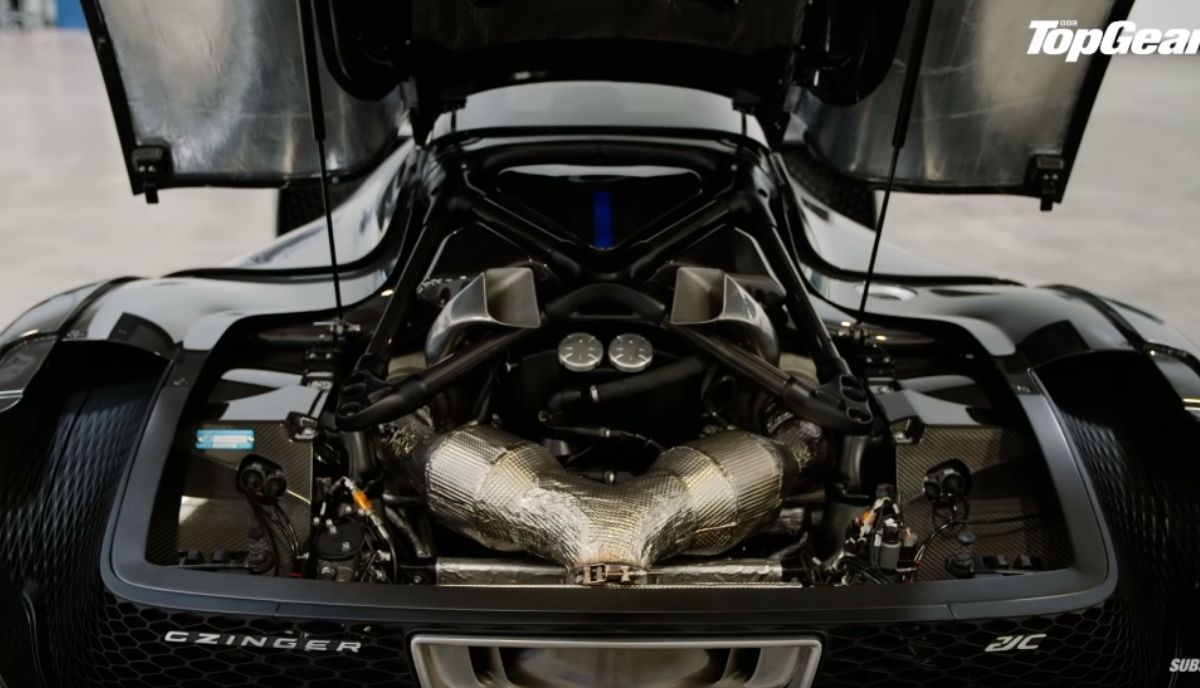

The interior component of 21C's powertrain is an ultra-compact 2.9-liter twin-turbo V-8 built and built in Czinger, drives real wheels with seven-step automatic transmission and in-house and is available in full-raceboxbox spec for fast switch times. . The small IV-8, 80-degree vee, four-cylinder valves, 9.5: 1 compression ratio, and flex-fuel capability, produce 950 hp at an alarming 10 500 rpm, says chief technology officer Gunner. , which means pumping 330hp per liter. The redline is 11,000 rpm.

The front has two 201-hp electric motors, one for each front wheel, which allows for continuous flexible torque output to improve handling, which can be adjusted by adjusting the pressure and decreasing the repetition of each wheel on a chassis with flexible mobility and active voice control system. E-motors are powered by a compact fast-charging, fast-discharge battery pack battery that is kept mounted with an engine-powered start-up system.

The total output of the system is 1,233 hp. By road specification, the 21C weighs just 2,756 pounds; the version of the track fits 2,685 pounds with feathers. That calculates the average weight of 2.23 pounds for each horse and 2.17 pounds for each horse, respectively. In essence, the Bugatti Chiron Pur Sport lugs 2.9 pounds per horsepower; McLaren Senna, 3.8 pounds per horsepower.

The 21C integrated combination and light weight is the direct result of a complex - and still secret - production process developed by the big business of Kevin Czinger, a company called Divergent 3D. Another name for the production of additional 3-D printing, although both Czinger and Gunner claim that the Deligent process, covered by more than 330 patents, extends far beyond, using software related to eliminating the need for traditional practices, as well as expensive tools and jigs.

The Divergent 3D production process allows small parts and components to be built, filtered, and tested online before the components are "printed" and integrated into the real world, saving time and minimizing waste. Czinger says that Divergent 3D has already given permission to make the machine to five of the world's leading car manufacturers, and that we will see a car on the road from one of them having a "printing" rear and bottom subframe assembly within a year.

What the 21C has to offer, however, is the suitability of Divergent 3D's low-volume production process, as well as its ability to use the right amount of goods in the right place, to reduce weight and cost. The suspension arms of 21C's spidery, made of high-performance alloy, have a natural appearance, as if they are older than they are either made or mechanized or stamped. The upper arms of control are, in fact, hollow, with a three-dimensional internal structure, which means that they measure a fraction of the custom-wrapped but very strong pieces of custom. "They look like things from nature," said Kevin Czinger about these parts, "because nature competes with material things and energy. It has to work well."

Only 80 CCzger 21Cs will be made, prices ranging from $ 1.7 million, and taxes. While the Divergent 3D process enables a significant reduction in production and production times, each 21C will be carefully completed and manually assembled at a company plant in Los Angeles, taking more than 3,000 hours to complete. The car is also in 50 countries legally in terms of output and crash rating and will be able to be officially sold in Europe.

When the 21C production operation is complete, what about it? “I think this gives us an opportunity to make a family of high-end cars built on this same design,” Gunner said. "With the flexibility we have, we can bring very different products to the market very quickly."

And while Kevin Czinger believes the Deligent 3D production system will bring about a major change in automaking since Henry Ford introduced the mobile production line, he is not willing to compete with any of the major manufacturers. "Cinger cars will always be the backbone of this technology," he said. "With our existing resources, I have been able to build a variety of non-existent vehicles."

No comments:

Post a Comment